Product Introduction

・The minimum resolution can reach 1N.m and factory accuracy reaches ±3%. The repeatability accuracy is ±3%, and the accompanying traceability torque verification report is provided. The TS version with torque sensor can achieve an accuracy of ±1%;

・The power system can rotate 360 degrees, and the memory-type mechanical locking system has no reactive force acting on the handle, which can prevent personal injury caused by mechanical failure;

・Spring type reaction arm can be quickly removed and replaced, improving work efficiency;

・After tightening, it can automatically retract, making it easy to remove the wrench;Lightweight and reliable ergonomic gun grip, increasing user comfort;

・The STW-CS series controller provides a simple and easy-to-use operating interface for all STW tools, allowing torque to be set through the human-machine interface, making operation simpler and more convenient;

・Workstations, operators, torque, and dates can be edited, and fastening data can also be exported via USB;

・It will automatically stop when the set torque is reached, and the tightening result is informed by visual signal light and buzzer;

・The counter calculates the number of times it has been used in real-time and maintenance times is set for automatic reminder, making it clear whether maintenance is needed immediately;

・There are three modes to choose from: torque mode, angle mode, and torque plus angle mode;Optional: Transmission system with torque sensor, capable of achieving dual closed-loop control of torque and angle, with TS added to the model;

・Support communication methods such as MODBUS and PROFIBUS, and can also add wireless communication modules to achieve management of IoT connection between upper computer and MES system;

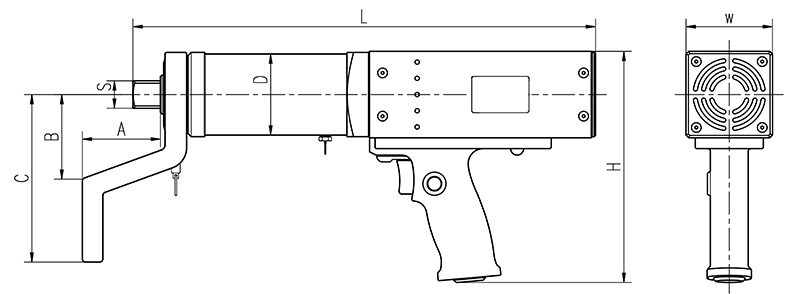

| Model | Torque(N.m) | Drive ShaftS(Inch) | No-load speed(Rpm) | L (mm) | H (mm) | D (mm) | A (mm) | B (mm) | C (mm) | Weight(Kg) |

| STW01 | 7-50 | 1/2″ | 58.6 | 325 | 210 | 75 | 45 | 45 | 90 | 6.6 |

| STW03 | 35-250 | 3/4″ | 49.2 | 335 | 210 | 75 | 50 | 54 | 110 | 7.1 |

| STW07 | 100-700 | 3/4″ | 32.4 | 385 | 210 | 75 | 50 | 54 | 110 | 8.1 |

| STW10 | 140-1000 | 3/4″ | 20.6 | 405 | 210 | 88 | 65 | 65 | 130 | 8.5 |

| STW21 | 300-2100 | 1″ | 9.1 | 430 | 210 | 75 | 75 | 75 | 150 | 10.5 |

| STW30 | 430-3000 | 1″ | 7.4 | 440 | 210 | 88 | 80 | 83 | 160 | 10.9 |

| STW40 | 570-4000 | 1″ | 4.8 | 450 | 210 | 95 | 80 | 83 | 160 | 14.5 |

| STW50 | 715-5000 | 1″or1-1/2″ | 4.8 | 450 | 210 | 95 | 80 | 83 | 160 | 14.5 |

| STW60 | 850-6000 | 1-1/2″ | 3.7 | 490 | 210 | 122 | 90 | 90 | 180 | 16.8 |

| STW70 | 1000-7000 | 1-1/2″ | 3.7 | 490 | 210 | 122 | 90 | 90 | 180 | 16.8 |

| STW80 | 1150-8000 | 1-1/2″ | 2.5 | 550 | 210 | 139 | 100 | 95 | 200 | 18.5 |

| STW100 | 1450-10000 | 1-1/2″ | 2.3 | 550 | 210 | 139 | 100 | 95 | 200 | 18.8 |

| STW120 | 1750-12000 | 1-1/2″ | 1.8 | 550 | 210 | 139 | 100 | 95 | 200 | 18.9 |