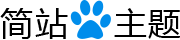

Product Introduction

・Standard configuration includes 2 pieces of 18V, 5Ah lithium batteries, and a fast charger that can be completed in 60 minutes, and optional configuration includes 8.0Ah and 12.0Ah batteries;

・Brushless motors are applicable for low explosion-proof situations and have strong and long-lasting power;

・The lightweight composite material body can absorb vibrations well and also protect handle from cold damage, with light weight and high efficiency;

・High torque without the need for a reaction arm, with strong spatial applicability;

・The factory accuracy reaches ±5%. The repeatability accuracy is ±3%, and the accompanying traceability torque verification report is provided;

・It will automatically stop when the set torque is reached, and the tightening result is informed by visual signal light and buzzer;

・The counter calculates the number of times it has been used in real-time, making it clear whether maintenance is needed immediately;

・Standard configuration: torque, bolt, and gear preset modes;

・The body can store 10,000 pieces of fastening data, which can be connected to the device through Type-C to monitor and export fastening data (workstation, operator, torque, and date), and achieve reversible data query;

・Optional: Wireless communication module can be added to connect to the upper computer or APP;

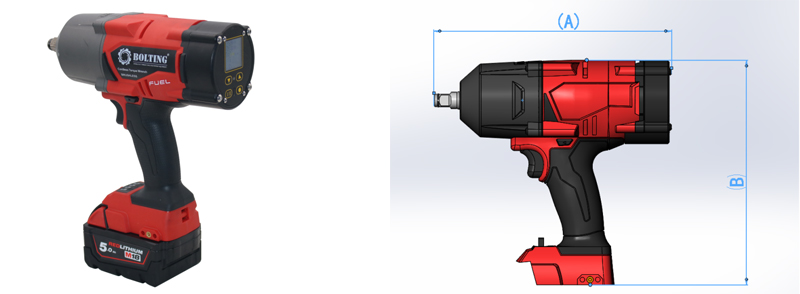

| Model | Operating Torque (N.m) | No-loadSpeed (Rpm) | Drive Shaft(Inch) | Length(mm) | Height(mm) | Impact Rate(ipm) | Noise Level (dbA) | Weight (Kg) |

| IBTW005 | 13-65 | 2400 | 3/8″ | 153 | 153 | 3200 | 96 | 1.5 |

| IBTW01 | 28-140 | 2400 | 1/2″ | 153 | 153 | 3500 | 96 | 1.9 |

| IBTW02 | 50-250 | 1800 | 1/2″ | 245 | 245 | 2100 | 101.5 | 3.3 |

| IBTW03 | 65-330 | 1800 | 3/4″ | 255 | 255 | 2400 | 101.5 | 3.6 |

| IBTW04 | 90-450 | 1650 | 1″ | 353 | 353 | 2500 | 96 | 5.0 |

Lithium battery impact wrench with added digital display control (not a case study, images only for display purposes)