Repair and installation of a nuclear equipment late at night

News 2025-10-13

At 10 o’clock on the night of June 10, 2016, Boting Machinery received a phone call from the Nuclear Construction Company, informing us that a nuclear power equipment was in urgent need of assembly and would undergo a high-pressure test the next day at 262.5 bar The time was pressing, and they hoped to receive professional technical support and equipment arrival at the site as soon as possible.

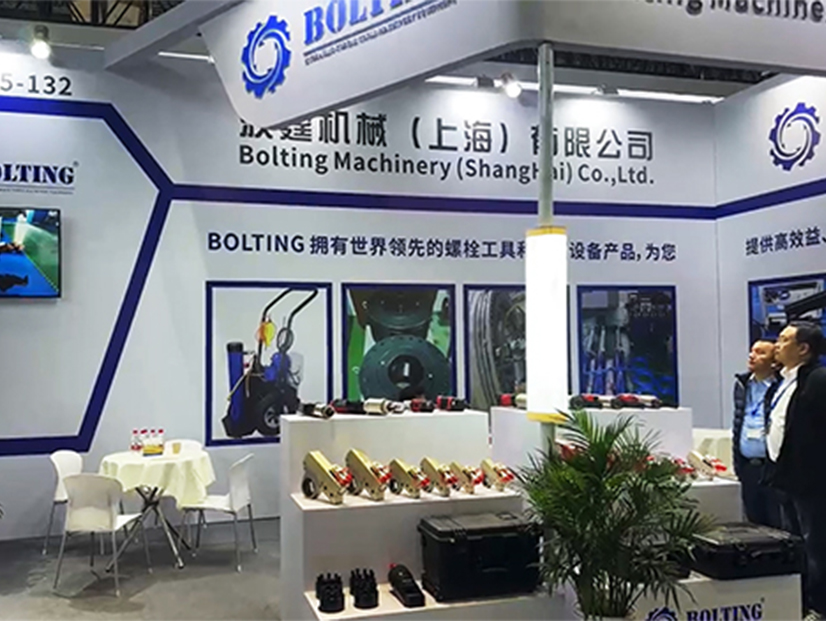

Working condition: S105 bolts, strength grade 12.9, the required tightening torque is 15000 N.m, total of 120 bolts need to be fastened for four sets of high-pressure flanges. Bolts N.m (20MXT) square drive hydraulic and a set of 17202 N.m (14XLCT) hollow hydraulic wrench were used to complete the emergency repair task.

Botiang Machinery immediately arranged for the hydraulic tools to be dispatched and sent two engineers to drive to the customer’s site overnight. They arrived at customer’s site at 11 p.m. Upon arrival, they found that the workers were resting and that the American-made hydraulic torque wrench they had borrowed earlier had its ratchet and pawl parts, and the hydraulic pump station was also unable to pressurize due to continuous high-pressure operation. A site supervisor earnestly shook hands one of the engineers and said, “I never expected you to come. The leadership has given us a mission that must be successful today.”

The on-site staff had a very serious communication, discussion and learning with the mechanical engineers of Botiang about the correct operation method of the hydraulic wrench As soon as the training ended, everyone started to get busy. The on-site workers who correspond to the two flanges were divided into two groups, each group of three people and the bolts were removed synchronously.

The installation was completed at around 6 o’clock in the morning, and at 7 o’clock, the customer used the water pressure pump to carry the pressure test, which was successful in one go with zero leakage.

After 8 hours of continuous emergency repair work, the two engineers from BOLTING (Bolt Engineering) provided full-time guidance and professional advice After all the work was completed, the person in charge of the site firmly shook hands with the BOLTING engineers and said: You have worked hard. BOLTINGBolt Engineering) always adheres to the principle of “leading technology, high quality and efficiency, customer first, and compliance with credit”, focusing on product quality and after- service, and has won an excellent reputation among users.