BOLTING 1600-ton PLC-controlled fully automatic synchronous lifting system (CNC intelligent cylinder synchronous control system) technical

Noticias 2025-09-05

| Parameters of other brands in the industry | BOLTING |

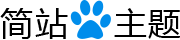

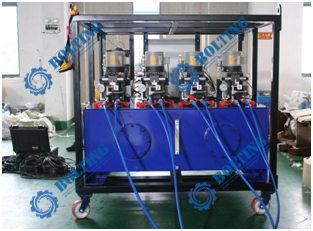

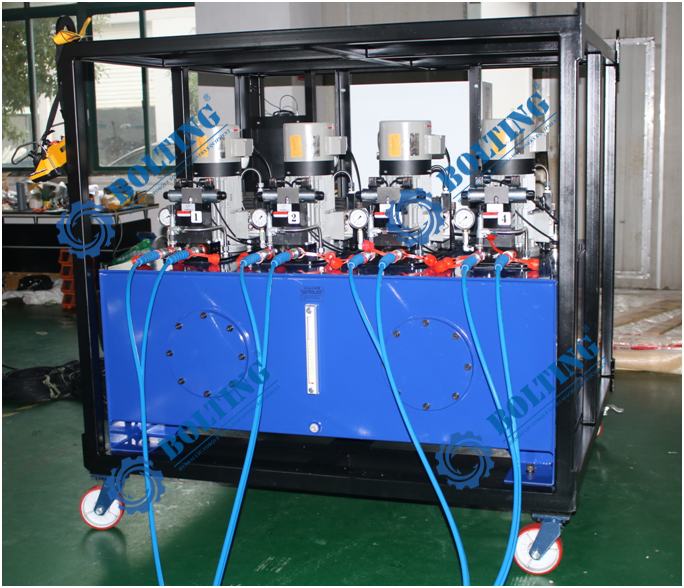

| Super high pressure hydraulic pump | |

| (1)The hydraulic power unit is equipped with two high-efficiency ZE series electric pumps from other brands to supply oil, under normal conditions one electric supplies oil to two hydraulic cylinders; (2)At the same time, one of the electric pumps can supply oil to the four hydraulic cylinders through an external pipeline; (3)High frequency electromagnetic directional valve for lifting/retracting control; (4)An oil tank with 800L of available hydraulic oil capacity provides ample oil for the system’s application and recirculating cooling The hydraulic oil cooler is configured to cool the hydraulic oil in time, preventing the hydraulic oil temperature from rising too fast during operation | (1)The hydraulic power unit is equipped with four HAWE high-efficiency RZ series electric pumps for oil supply, with one electric pump oil to one hydraulic cylinder under normal conditions; (2)At the same time, it can be connected to an external pipeline to replace one of the original four pumps to oil to the connected hydraulic cylinder; (3)A high-frequency electromagnetic directional valve is used for lifting/retracting control; (4)An oil with a usable hydraulic oil capacity of 800L provides sufficient oil for the system’s application and circulating cooling; The configuration of a hydraulic cooler can cool the hydraulic oil in time to prevent the hydraulic oil temperature from rising too fast during operation; |

|  |

|  |

|  |

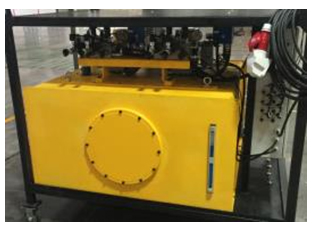

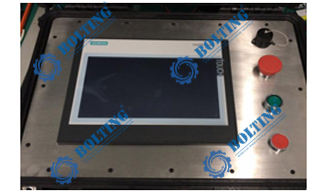

| PLC electrical control system | |

| (1)10” LCD touch screen human-machine interface; (2)Allows the operator to input required parameters prepare for the lifting operation; (3)Displays the lifting operation status including displacement and hydraulic working pressure in real time; (4)The pressure detection feature prevents undesired events due to the failure of the cylinder or displacement sensor during lifting; (5)To protect the PLC and facilitate mobility, PLC control console is mounted on a steel stand; In addition to being operable from the main control console, it can also be remotely operated the HBC wireless controller, which facilitates close observation of the load lifting process and cylinder status; | 10” LCD touch screen human-machine interface; Allows the operator to input required parameters to prepare for the lifting operation; Displays the lifting operation status including displacement and hydraulic working pressure in real time; The pressure detection feature prevents undesired events due to the failure of the cylinder or displacement sensor during lifting; To protect the PLC and facilitate mobility, the PLC control console is mounted on a steel stand; In addition to being operable from the main control console, it can also be remotely operated via the HBC wireless controller, which facilitates close observation of the load lifting process and cylinder status; |

|  |

|  |

|  |

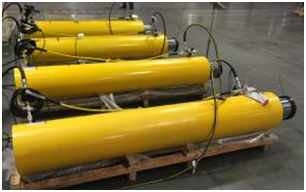

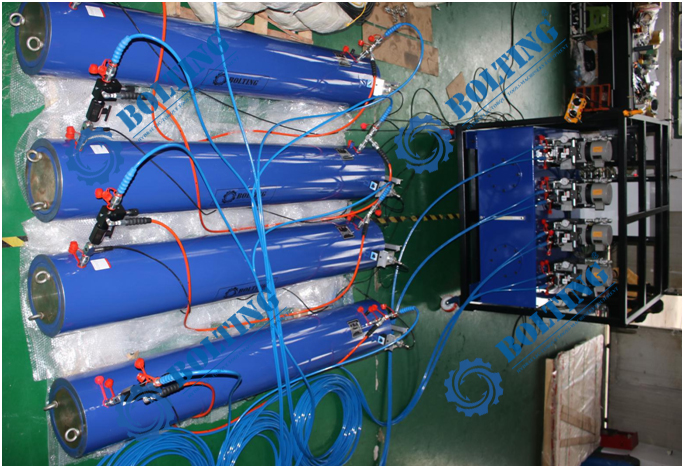

| Hydraulic cylinder | |

| (1)For lifting/lowering the load; (2)Hydraulic cylinders with hydraulic balancing valves can only used independently in a synchronized lifting system; (3)Both the upper and lower chambers of the hydraulic cylinders with hydraulic balancing valves shall be equipped with safety valves to prevent over; This system requires the hydraulic cylinders to be placed in and secured by a specially designed lifting bracket before use; | (1)For lifting/lowering the load; (2)Hydraulic cylinders with hydraulic balancing valves can only be used independently in a synchronized lifting system; (3)Both the upper and lower chambers of the hydraulic cylinders with hydraulic balancing valves shall be equipped with safety valves to prevent overloading; This system requires the hydraulic cylinders to be placed in and secured by a specially designed lifting bracket before use; |

|  |

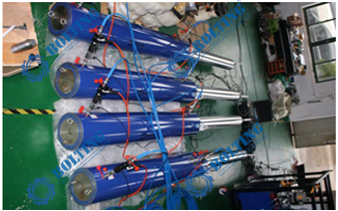

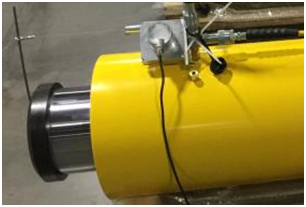

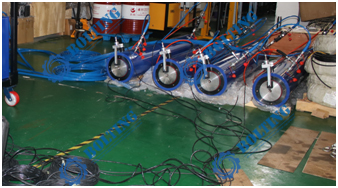

| Displacement sensor | |

| (1)For multi-point synchronous lifting operation; (2)Specially designed for severe working conditions; The figure shows the situation of simulation debugging stage; | (1) For multi-point synchronous lifting operation; (2) Specially designed for severe working conditions; (3) The figure shows the preparation for shipment in the simulation commissioning stage; |

|  |

1600-ton PLC-controlled fully automatic synchronous lifting system (CNC intelligent cylinder synchronous control system) under commissioning with a stroke of 1.8 meters

1600-ton PLC-controlled fully automatic synchronous lifting system (CNC intelligent cylinder synchronous control system) under commissioning with a stroke of 1.8 meters

1600-ton PLC-controlled fully automatic synchronous lifting system (CNC intelligent cylinder synchronous control system) under commissioning with a stroke of 1.8 meters

1600-ton PLC-controlled fully automatic synchronous lifting system (CNC intelligent cylinder synchronous control system) under commissioning with a stroke 1.8 meters