Precautions for synchronous pre tightening bolts with lithium battery torque wrench

News 2025-06-18

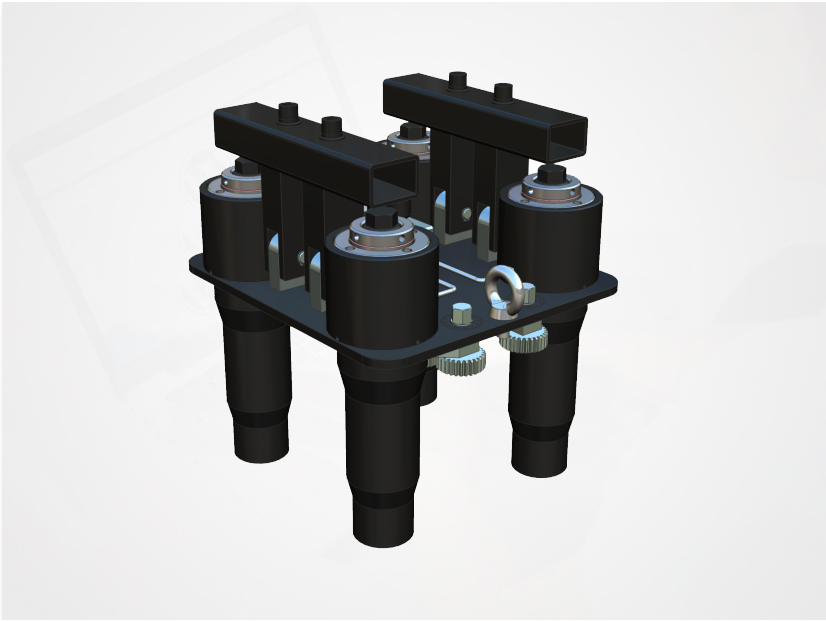

Lithium battery torque wrenches are becoming increasingly popular in various working conditions due to their high precision, fast pre tightening, and portability. When using a lithium battery torque wrench for bolt synchronous pre tightening, there are several key points that need to be noted to ensure that the pre tightening effect meets expectations.

Firstly, choosing a reliable lithium torque wrench is crucial. There are many brands in the market, so it is essential to choose products with reliable quality and torque accuracy that meet the requirements. If the pre tightening torque does not meet the requirements, it may cause the bolt to loosen or fail.

Secondly, during synchronous pre tightening, the same model of lithium torque wrench produced by the same manufacturer should be used to ensure minimal error and even distribution of bolt pre tightening force.

Thirdly, ensure that each lithium torque wrench participating in synchronous pre tightening has sufficient power before construction to avoid insufficient output torque due to insufficient power.

When using a lithium battery torque wrench for bolt synchronous pre tightening, flange bolts should be numbered and grouped in the same way as using a hydraulic wrench, and pre tightening should be completed step by step in sequence.

Due to the fact that lithium battery torque wrenches are not controlled by the same system and are operated by different operators, achieving uniform force distribution requires coordination and consistency among operators. Therefore, operators need to receive professional torque pre tightening training and possess relevant knowledge.