How to choose a brand of electric torque wrench for charging?

News 2025-08-13

Electric torque wrenches are highly favored by construction units in some industries for their convenience, speed, and ease of operation during maintenance and installation operations. Especially for charging electric torque wrenches, they have become the most widely used bolt tightening and dismantling tool on site after hydraulic torque wrenches. So, how to choose an excellent brand of charging electric torque wrench?

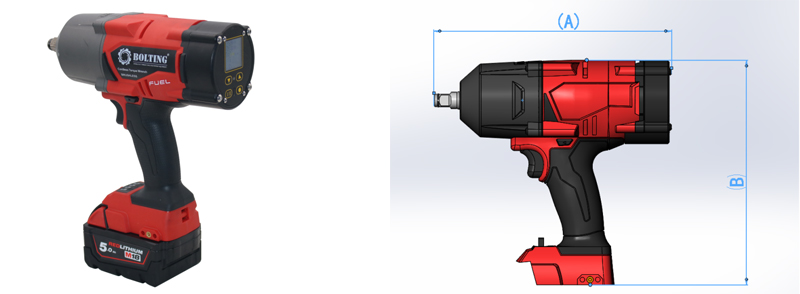

We know that when choosing a rechargeable electric torque wrench that is different from a regular electric impact wrench, the first thing to consider is whether the torque range and accuracy of the electric torque wrench can meet the requirements of the working conditions for bolt pre tightening. If the accuracy is too low, it cannot guarantee that the bolt pre tightening will reach the preset value, which means it is likely to result in unqualified pre tightening effect.

Next is the rotational speed. The reason why many non key flanges in chemical maintenance sites use rechargeable electric torque wrenches for synchronous fastening is that although their accuracy and torque are not as good as hydraulic wrenches, they are superior in terms of fast speed and high efficiency, which greatly helps with construction progress. So, the speed per minute is also an important indicator when selecting a charging torque wrench.

Another factor is battery capacity and power. If the power of the charging torque wrench is small, the power is insufficient, and the battery capacity affects the working time of a single charge, which in turn affects efficiency. Therefore, it also needs to be compared and considered.

It is also necessary to compare whether the weight and exterior design are suitable for one’s own working environment. For example, if the weight of the wrench is too large, it is not suitable for high-intensity and long-term handheld operations. Some designs cannot be used due to space limitations of working condition bolts.

Finally, it should be noted whether the design of the charging torque wrench takes into account the impact of reaction force and noise on the operator, and whether long-term use by maintenance and installation industry practitioners will have an impact on human arms and hearing.